Blow moulding

Complex shapes without compromising on quality.

Blow moulding

Extrusion Blow moulding is a well-established production process in which hollow shapes are blown using plastic granules (thermoplastics). Each cycle, the blow moulding machine produces a shape almost immediately suitable for finishing. Most thermoplastics are suitable for this process, but the most widely used are High Density Polyethylene (HDPE) and polypropylene (PP).

Materials, colours, sizes

All colours are possible, including semi-transparent versions. Zuiderplastic also produces plastic compounds, in which the properties of the compound are matched to the subsequent use of the final product. Dimensions of products can range from 10 cm to 60 cm.

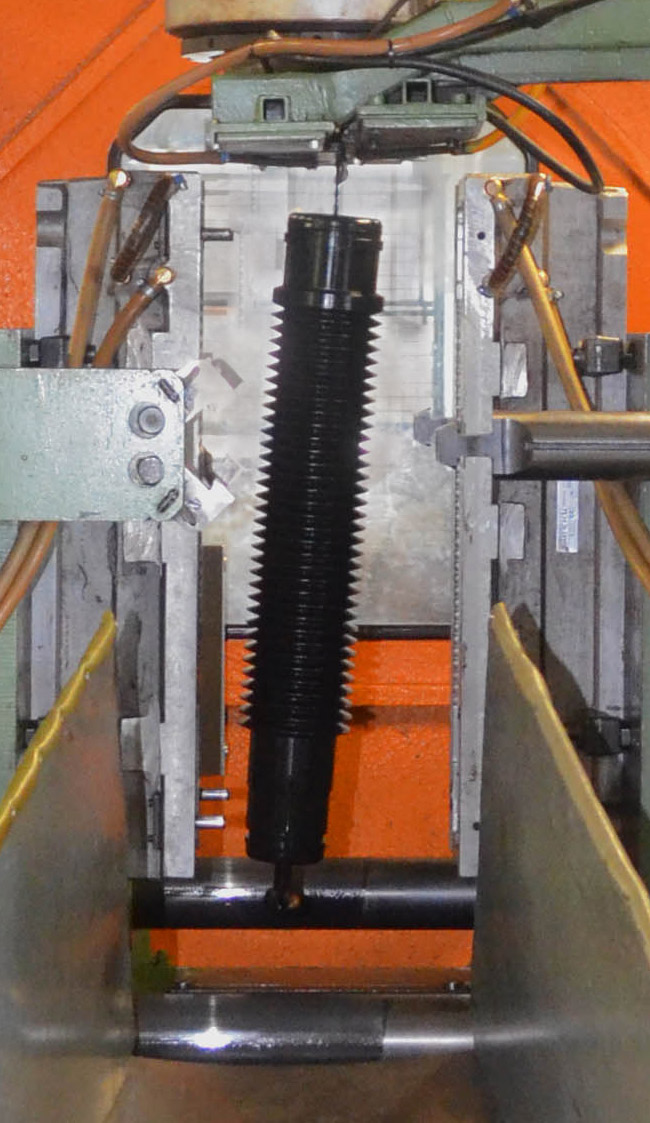

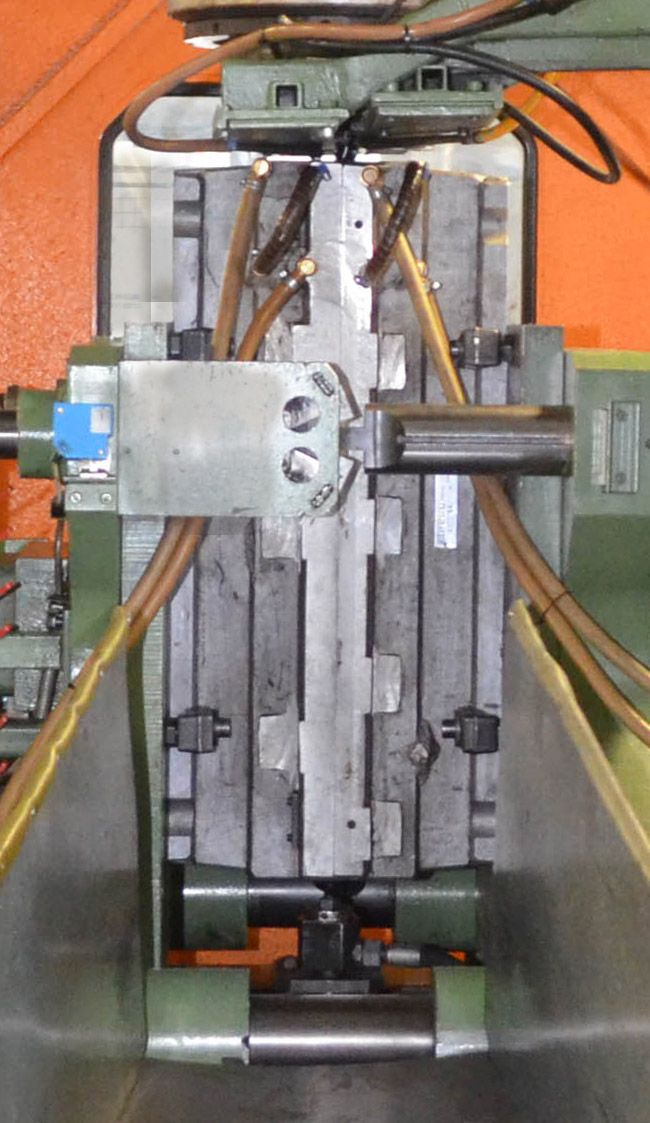

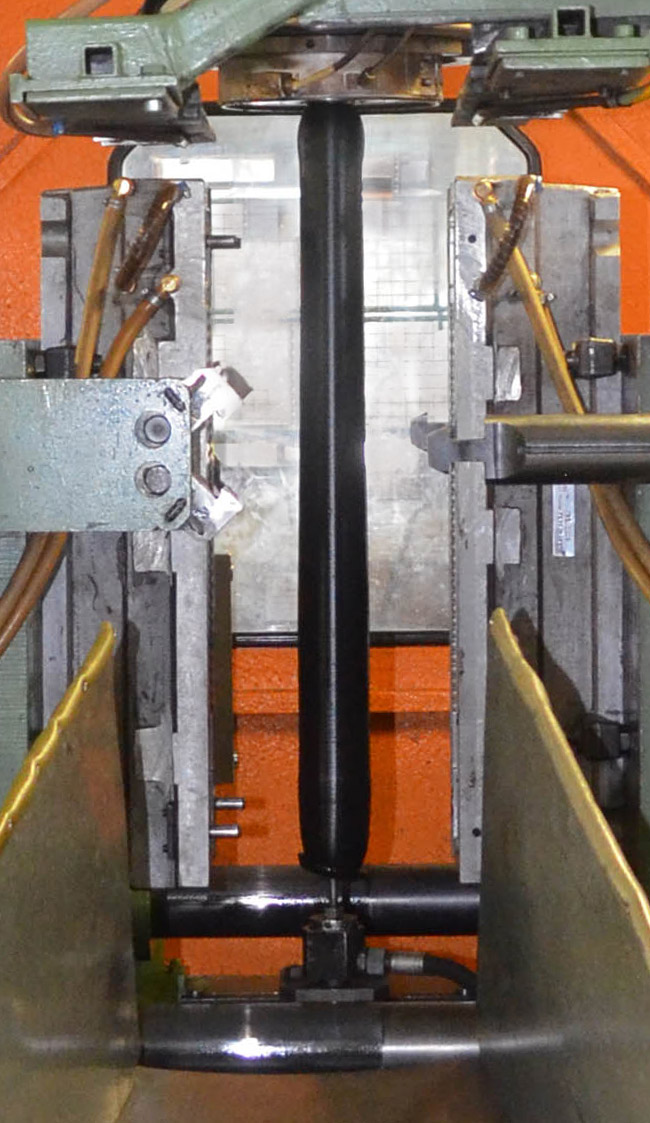

Blow moulding: the process

Blow moulding is a three phase process:

- A thermoplastic is heated and extruded into a tubular form.

- The softened plastic tube is then clamped in a two piece aluminium mould and inflated against the wall of the mould with compressed air.

- Water cools the mould, the mould cools the product and the plastic takes the shape of the inside of the mould. The product is removed and possibly mechanically or manually finished.

Watch the video of the process

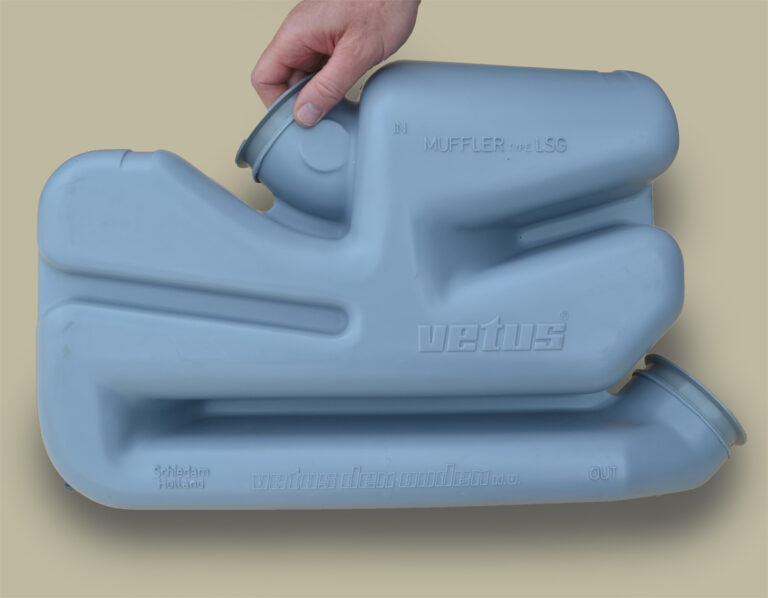

Specialist in complex shapes

The blow-moulding technique requires a relatively low investment compared to other techniques. This makes it well suited for production runs from 250 to 5000 units (depending on the complexity and size). This technique is especially suitable for complex shapes, difficult transitions and fine detailing, without compromising on quality. Challenging shapes are a speciality of Zuiderplastics.

Why blow moulding?

- Extremely suitable for complex shapes, difficult transitions and high detail

- Ideal for series of 500 to 10,000 pieces, larger editions also possible

- Products are strong, low maintenance and last a long time

- Relatively low investment costs per product

- Possible with different thermoplastics such as HDPE and PP

- Choice of all colors and semi-transparent

Would you like to know whether Zuiderplastics also has a customized solution for you?

Let’s meet!