Finishing and assembly

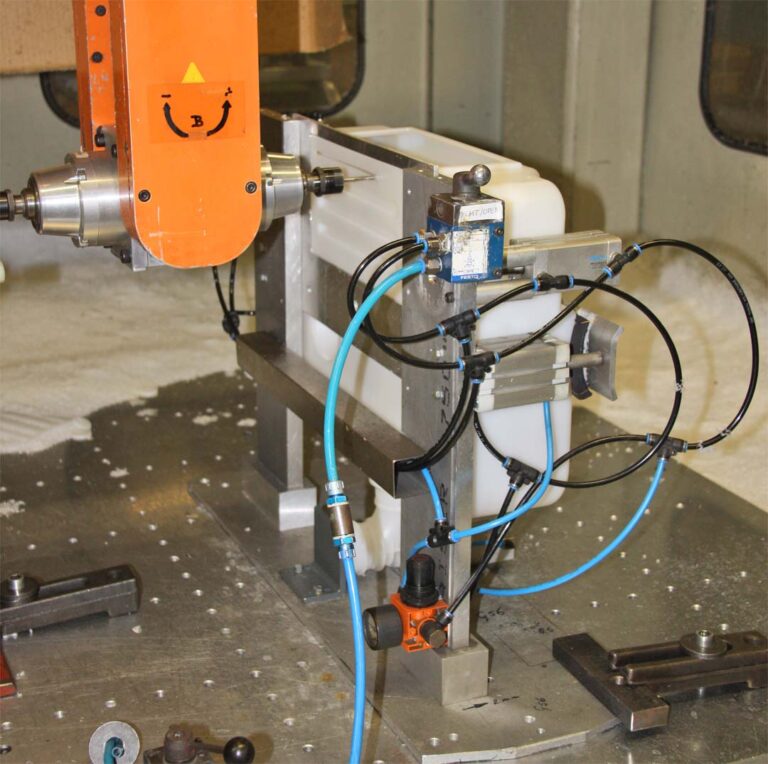

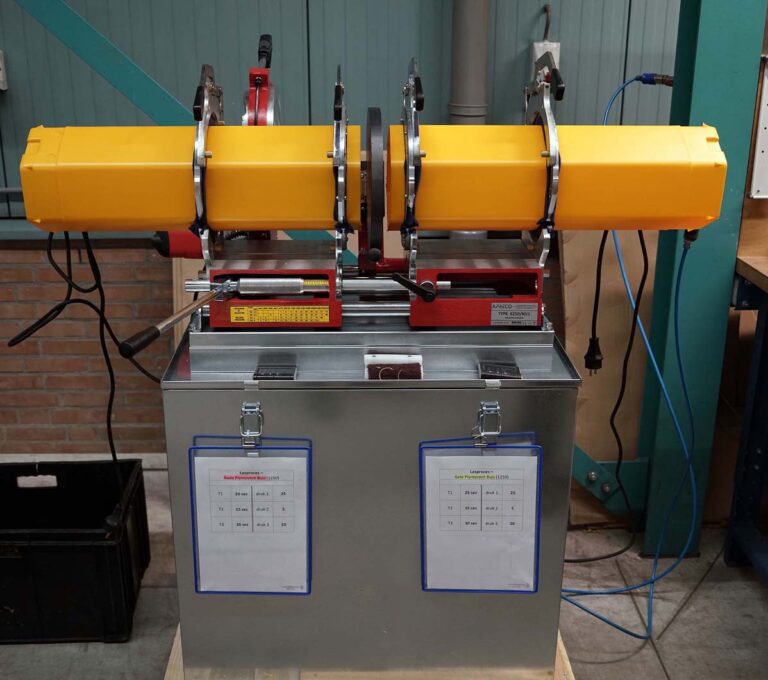

Zuiderplastics also offers various post-processing techniques, including CNC milling, punching, drilling, sawing and plastic welding.

FINISHING

After the product has been blown, it can be delivered without finishing. Zuiderplastics also offers a variety of finishing techniques, including CNC milling, punching, drilling, cutting, plastic welding. Our staff ensures that the necessary technology is appropriately and efficiently.

ASSEMBLY

This is also true for installation and assembly. Zuiderplastics has extensive experience with products consisting of several plastic components and with the processing of components consisting of a variety of materials. The client is provided with a (semi-finished) product immediately ready for subsequent installation or for sale. This saves time and money.

Would you like to know whether Zuiderplastics also has a customized solution for you?

Let’s meet!