Our method

Quickly come up with creative solutions with a hands-on mentality

Our method

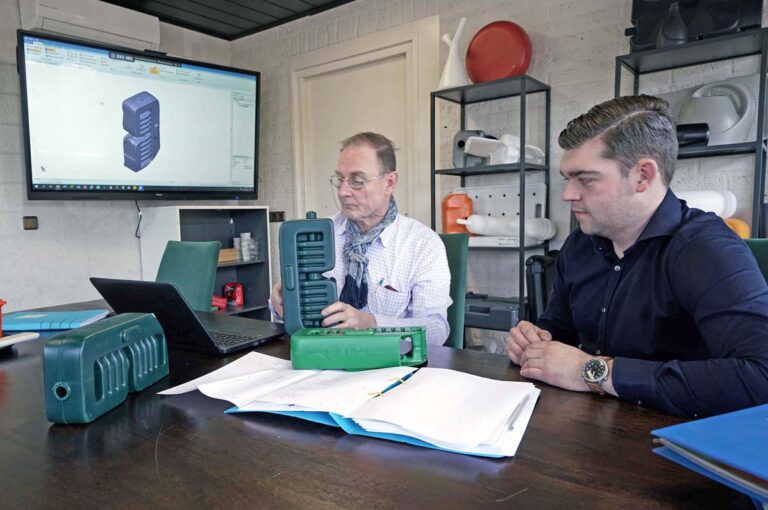

Zuiderplastics produces custom works: technical components or half-finished products for technical devices such as HVAC systems, boat engines and agricultural machinery. Mostly it involves complex shape, devised, engineered and manufactured in close cooperation with the client. Zuiderplastic achieves creative solutions fast with its hands-on mentality.

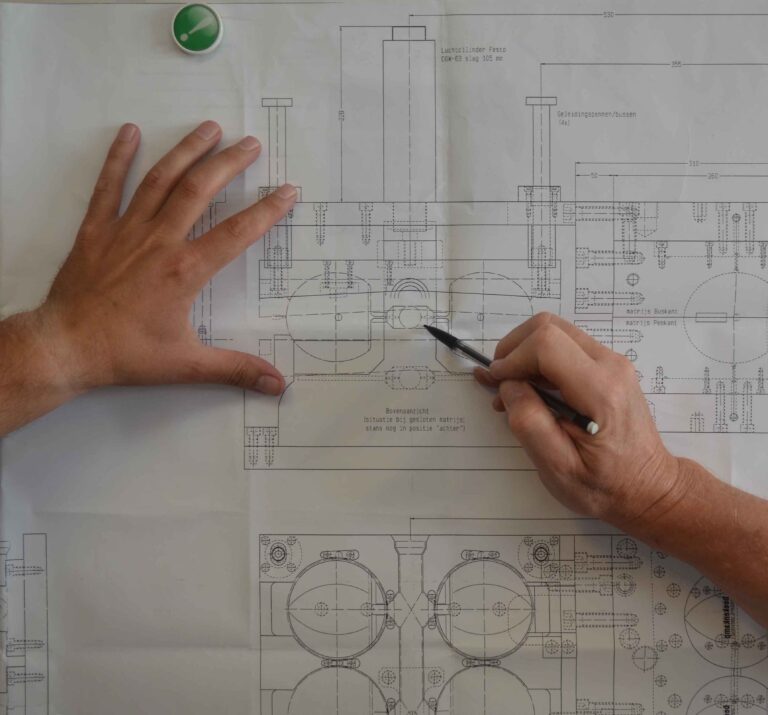

Preparatory phase

In this preparatory phase, we discuss the requirement of the products with the client on the basis of specifications, a sketch or a work plan. After possible optimisation of the design, we can make a clear offer for the mould and for the production, with or without assembly and finishing.

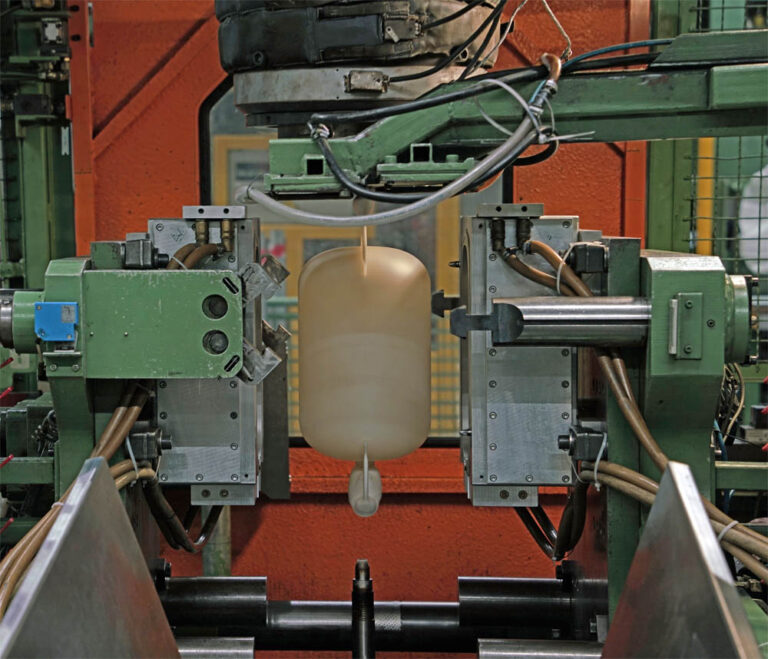

Manufacturing

When the mould has been delivered and tested, we can plan your production and organise the required final assembly and finishing, such as CNC milling, plastic welding, sawing, drilling or punching. This organisation is done in close consultation with the people in the workplace: they have the knowledge and ability to establish the optimum method and order of work.

Logistics

Products can be directly delivered to the client ex-works or indirectly through the warehouse of Zuiderplastic (just in time). Our logistics process is adapted to deliver on demand. We manage the (buffer) stock and you always have your products available for further installation or sale. The mould remains the property of the client and is stored in our warehouse. The mould remains in storage if the client is satisfied. This allows us to see the client satisfaction in our storage.

After sales

Our services do not stop after the delivery. We keep in touch with the client about the quality of the delivery and the performance of the (half) product. We immediately address comments and possible complaints in the production process. Our lines and our response times are brief.

Would you like to know whether Zuiderplastics also has a customized solution for you?

Let’s meet!